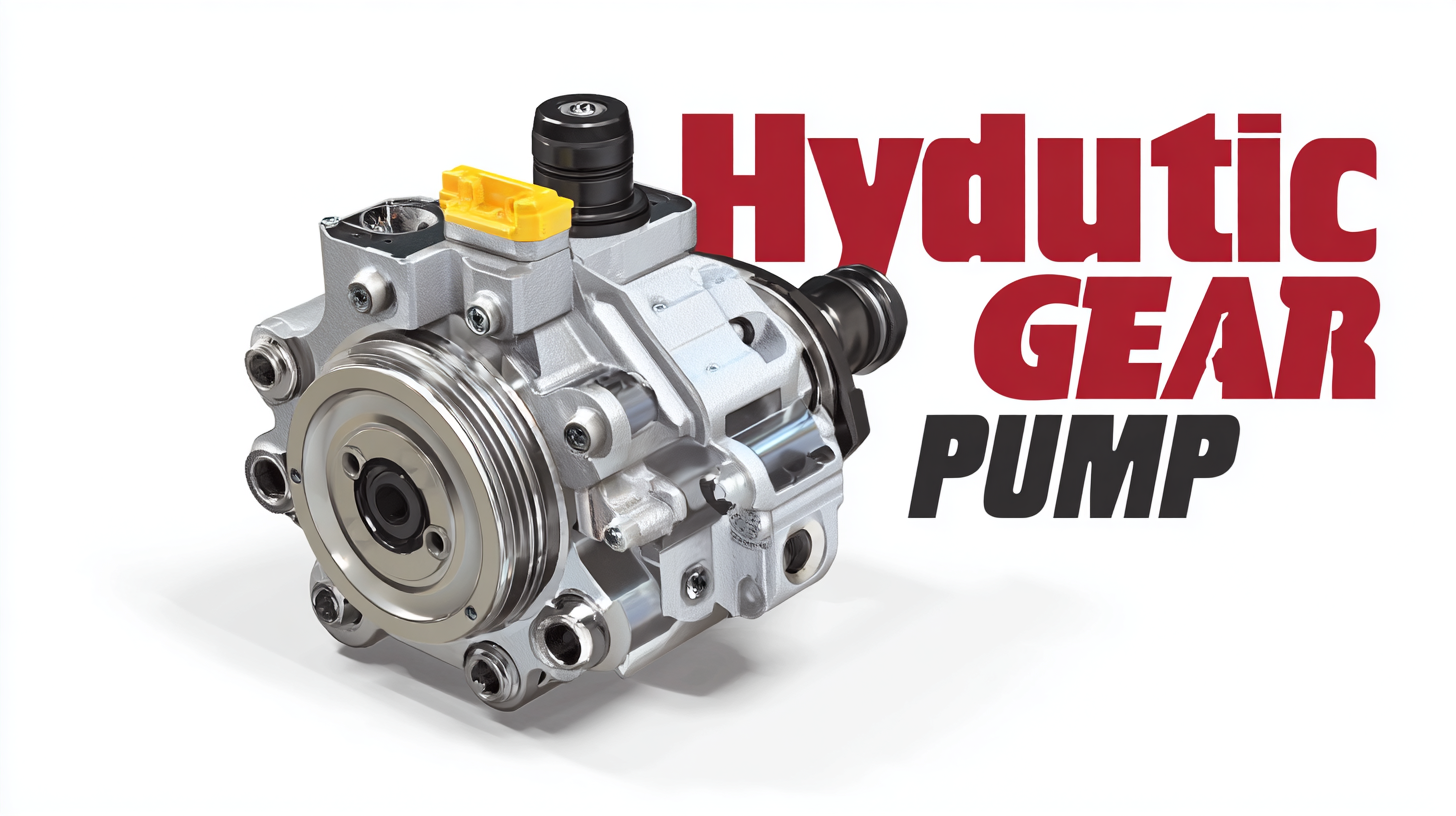

In the rapidly evolving landscape of industrial technologies, understanding and leveraging the trends that define 2025 is essential for enhancing the performance of Hydraulic Gear Pumps. As industries move towards greater efficiency and sustainability, the incorporation of digital solutions and innovative practices becomes paramount. This blog aims to explore how specific industry trends can be harnessed to optimize the functionality and reliability of Hydraulic Gear Pumps, ultimately leading to improved operational outcomes.

We will provide actionable tips and insights on integrating cutting-edge technologies, streamlining processes, and adapting to market shifts, ensuring that your Hydraulic Gear Pump not only meets but exceeds the demands of modern applications.

Join us as we delve into the key strategies that will position your hydraulic systems for success in the coming years.

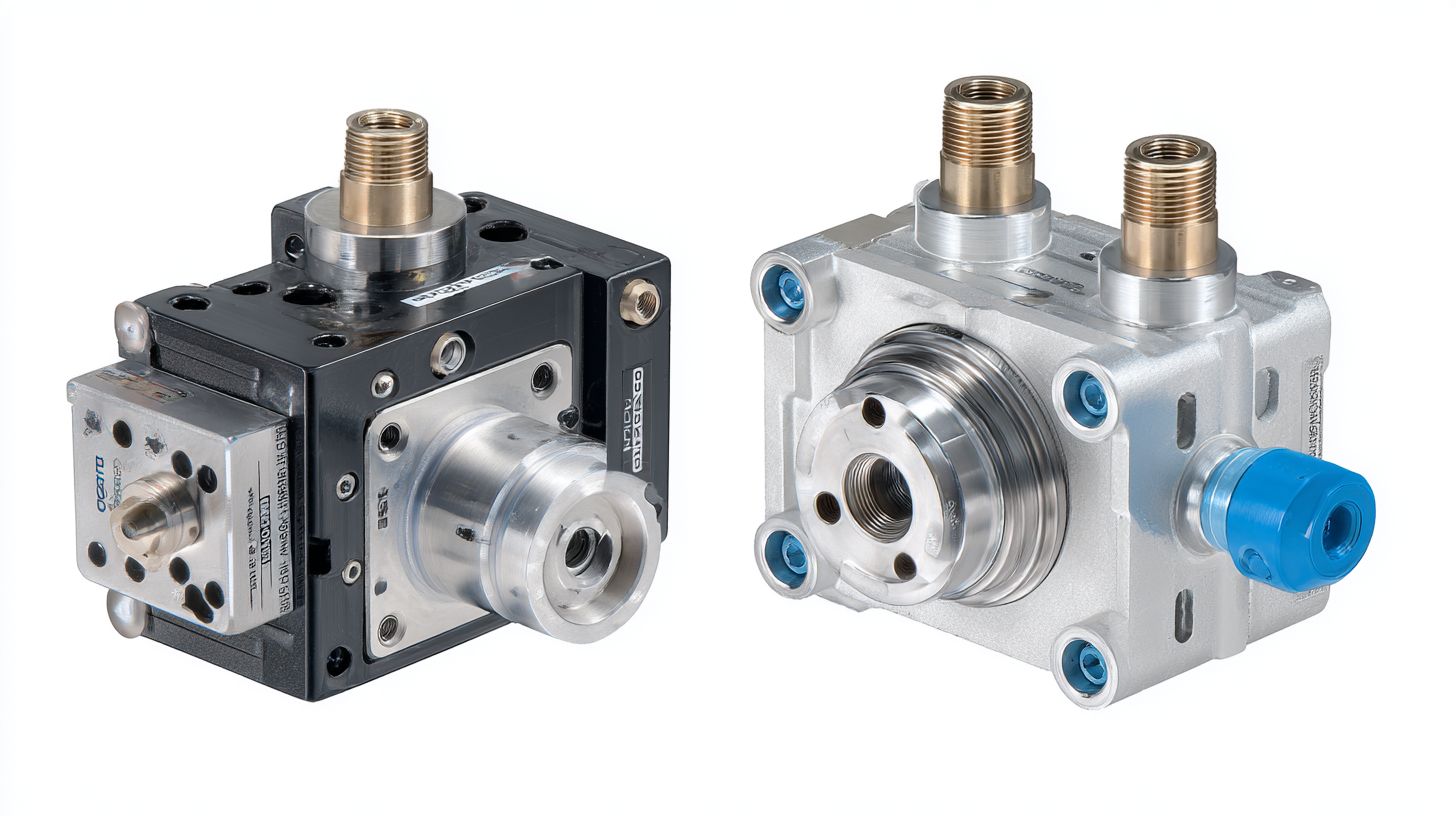

The performance and longevity of hydraulic gear pumps are increasingly influenced by the ongoing advancements in materials science. With the industry expected to grow by 4.8% annually, driven by significant demand in construction and agriculture, leveraging advanced materials can enhance durability and efficiency, leading to improved overall performance. According to the "Hydraulic Equipment Market Report 2023", high-performance composites and engineered metals are paving the way for longer-lasting pump components, reducing the frequency of replacements and maintenance costs.

Advanced materials such as polymer blends and low-friction coatings are critical in minimizing wear and tear under high-pressure conditions. Research by the American Society of Mechanical Engineers (ASME) indicates that pumps utilizing such materials can experience a reduction in operational fatigue by up to 30%. Moreover, these innovations not only extend the lifespan of hydraulic gear pumps but also contribute to energy savings, as more efficient materials reduce drag and improve fluid dynamics. Understanding and incorporating these advancements will be pivotal for manufacturers seeking to stay competitive in the evolving landscape of hydraulic technologies.

As we advance towards 2025, the integration of smart manufacturing technologies is set to revolutionize hydraulic gear pump performance. By implementing Internet of Things (IoT) devices and advanced analytics, companies can monitor and optimize pump operations in real-time. These technologies enable predictive maintenance, reducing unexpected downtime and ensuring that pumps operate at peak efficiency. For example, sensors can track variables like pressure, temperature, and flow rates, allowing manufacturers to fine-tune their systems dynamically for maximum output.

Furthermore, leveraging artificial intelligence (AI) in process automation can lead to significant enhancements in hydraulic gear pump production. AI algorithms can analyze data patterns and predict potential failures before they occur. This not only extends the lifespan of pump systems but also saves costs associated with repairs and replacements. The adoption of smart manufacturing can empower organizations to achieve unprecedented levels of efficiency and productivity, reinforcing their competitive edge in the industry. By embracing these technologies, manufacturers can ensure that their hydraulic gear pumps perform optimally, meeting the ever-increasing demands of various applications.

| Trend | Description | Impact on Efficiency (%) | Smart Technology |

|---|---|---|---|

| IoT Integration | Connecting hydraulic pumps to IoT devices for real-time data monitoring. | 15% | Remote Diagnostics |

| Predictive Maintenance | Using data analytics to predict equipment failures before they occur. | 20% | Sensor Technologies |

| Automation | Incorporating automated systems for precise control in hydraulic operations. | 25% | Robotics |

| Energy Efficiency | Implementing energy-saving technologies in hydraulic systems. | 30% | Smart Grids |

| Data Analytics | Utilizing big data to optimize hydraulic system performance. | 18% | Data Mining Tools |

In an ever-evolving industrial landscape, staying attuned to emerging global market demands is crucial for optimizing hydraulic gear pump performance. As industries shift towards sustainability and efficiency, manufacturers must adapt their product designs to meet these needs. For instance, trends indicating a rise in environmentally friendly practices are prompting companies to invest in hydraulic gear pumps that utilize bio-based oils and have reduced energy consumption. This not only meets regulatory standards but also appeals to environmentally conscious buyers.

Moreover, the increasing integration of smart technology in hydraulic systems presents a significant opportunity for innovation. By leveraging data analytics and IoT (Internet of Things), manufacturers can enhance the functionality of hydraulic gear pumps. This allows for predictive maintenance, reduced downtime, and better operational efficiency, aligning with the demands of a fast-paced market. Adapting to these technological trends will not only improve product performance but also position companies as leaders in a competitive industry, demonstrating their commitment to catering to the evolving preferences of global customers.

The integration of sustainability practices into the production of hydraulic gear pumps is becoming increasingly critical as industries strive to meet the demands of a changing environment. Recent projections indicate that the global hydraulic pumps market is set to grow significantly, with an anticipated CAGR that could reach up to 17 times from 2025 to 2035. This surge reflects the rising demand for efficient hydraulic systems that not only enhance performance but also adhere to eco-friendly practices. By leveraging advanced materials and energy-efficient technologies, manufacturers can optimize the performance of hydraulic gear pumps while minimizing their environmental impact.

Moreover, the design and simulation analysis of devices such as flexible clamping and conveying machines for harvesting green leafy vegetables exemplify the practical application of sustainable practices in engineering. Such innovations enhance production efficiency and are part of a broader movement toward energy-efficient technologies in agricultural machinery. By focusing on sustainable production methods and integrating these principles across various sectors, industries can improve operational efficiency while contributing to a greener future and fulfilling regulatory expectations regarding environmental stewardship.

In the fast-evolving landscape of hydraulic gear pumps, leveraging data analytics has become a game-changer for performance monitoring and management. By harnessing vast amounts of operational data, manufacturers can identify inefficiencies and areas for optimization, leading to enhanced performance and reduced downtime. Predictive analytics tools can analyze historical data patterns, allowing engineers to anticipate failures before they occur and implement timely maintenance strategies, ultimately extending the life of equipment.

Moreover, integrating real-time data analytics enables operators to monitor pump performance continuously. By using advanced algorithms and IoT devices, performance metrics such as pressure, flow rate, and temperature can be tracked in real time. This immediate feedback loop empowers teams to make informed decisions quickly, ensuring that hydraulic systems operate at peak efficiency. The focused approach of utilizing data analytics not only streamlines operational processes but also contributes to achieving greater energy savings, lower costs, and increased overall reliability in hydraulic gear pumps.