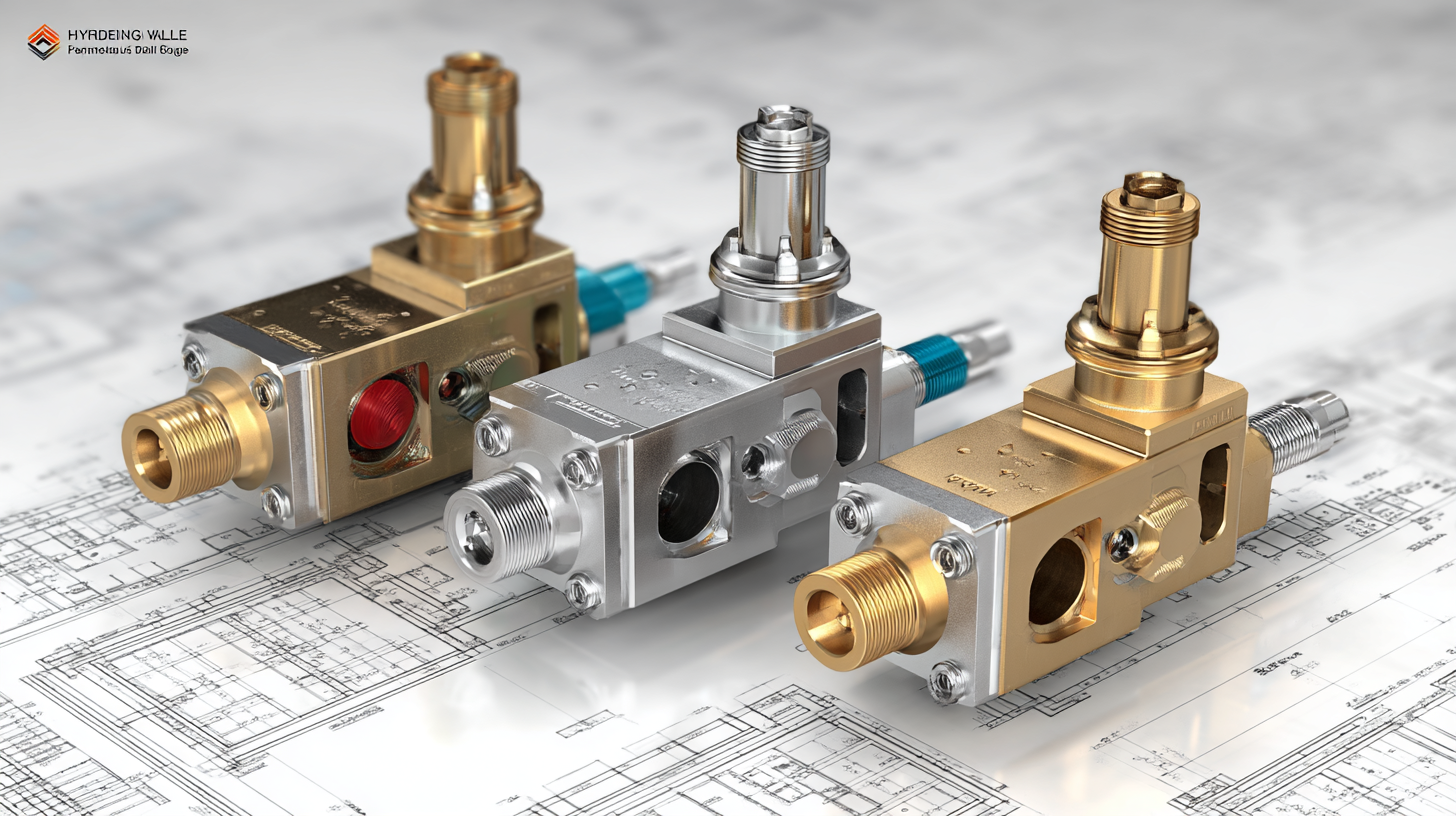

As we approach 2025, the hydraulic valve industry is poised for significant transformation fueled by technological advancements and market demands. This blog will explore the emerging trends that are shaping the future of hydraulic valves, focusing on innovations that enhance efficiency, reliability, and adaptability in various applications. Global buyers must stay informed about these developments to make educated choices that will impact their operational capabilities and competitive edge. From the integration of smart technology and IoT to advancements in materials and design, understanding these trends is crucial for navigating the evolving landscape of hydraulic valve technologies. Join us as we delve into this ultimate guide, highlighting essential insights and expectations for the hydraulic valve sector in the coming years.

Hydraulic valve technology is undergoing significant transformation, driven by advancing technologies and evolving market demands. According to a recent report by Research and Markets, the global hydraulic valve market is projected to reach USD 8.3 billion by 2025, growing at a CAGR of 4.2%. This growth is largely attributed to the increasing adoption of automation in various industries, such as manufacturing, agriculture, and construction. As companies strive for efficiency and precision, the development of smart hydraulic valves that incorporate IoT capabilities has emerged as a key trend in this sector. These valves enable real-time monitoring and performance optimization, leading to reduced downtime and enhanced operational efficiency.

Furthermore, innovations in materials and design are paving the way for more sustainable hydraulic valve solutions. A study published by the International Journal of Fluid Power highlights the role of composite materials in reducing the weight and energy consumption of hydraulic systems. This focus on sustainability aligns with global efforts to reduce carbon footprints amidst regulatory pressures. Additionally, the integration of advanced control systems, such as proportional and servo-controlled valves, is enhancing the adaptability and responsiveness of hydraulic applications. As the industry heads towards 2025, these emerging technologies will undoubtedly shape the future landscape of hydraulic valve innovation, meeting the demands of a dynamic market.

| Technological Innovation | Key Features | Expected Adoption Rate by 2025 | Impact on Efficiency (%) | Target Industries |

|---|---|---|---|---|

| Smart Hydraulic Valves | IoT Integration, Real-time Monitoring | 40% | 25% | Manufacturing, Agriculture |

| Electric Actuated Valves | Energy Efficiency, Low Maintenance | 30% | 20% | Construction, Oil & Gas |

| High-Pressure Valves | Durability, Increased Flow Capacity | 25% | 15% | Hydraulics, Aerospace |

| Biodegradable Hydraulic Fluids | Eco-Friendly, Non-Toxic | 35% | 10% | Agriculture, Mining |

| Modular Valve Systems | Flexibility, Easy Maintenance | 45% | 30% | Automotive, Robotics |

The global hydraulic valve market is experiencing significant shifts, particularly due to the influence of Chinese manufacturing. As one of the largest producers and exporters of hydraulic components, China has emerged as a key player, offering cost-effective solutions without compromising on quality. This rise in manufacturing capacity has enabled numerous international buyers to source advanced hydraulic valve technologies, thereby enhancing their operational efficiencies and reducing costs.

Chinese manufacturers are leveraging cutting-edge technologies and innovative design processes to stay competitive. With a focus on automation and precision engineering, they are developing hydraulic valves that meet global standards and cater to various industries, from construction to aerospace. As demand for sustainable and efficient hydraulic systems grows, Chinese companies are also prioritizing eco-friendly manufacturing practices, positioning themselves as leaders in the shift towards greener technologies. This trend not only benefits local industries but also reshapes the dynamics of the global market, making China an indispensable partner for buyers seeking advanced hydraulic solutions in 2025 and beyond.

Chinese manufacturers are leveraging cutting-edge technologies and innovative design processes to stay competitive. With a focus on automation and precision engineering, they are developing hydraulic valves that meet global standards and cater to various industries, from construction to aerospace. As demand for sustainable and efficient hydraulic systems grows, Chinese companies are also prioritizing eco-friendly manufacturing practices, positioning themselves as leaders in the shift towards greener technologies. This trend not only benefits local industries but also reshapes the dynamics of the global market, making China an indispensable partner for buyers seeking advanced hydraulic solutions in 2025 and beyond.

The hydraulic valve market is poised for significant advancements by 2025, driven by technological innovation and the growing need for efficiency in various industrial applications. Next-generation hydraulic valves are expected to feature smart technology integration, enhanced durability, and superior performance capabilities. According to a recent market analysis by Research and Markets, the hydraulic valve sector is projected to grow at a CAGR of 5.6%, reflecting an increasing demand for higher precision and responsiveness in hydraulic systems.

One of the key benefits of these next-generation valves is their ability to improve operational efficiency. Advanced designs using lightweight materials not only reduce the overall weight of hydraulic systems but also minimize energy consumption by up to 15%, as reported by the Fluid Power Journal. Furthermore, features such as integrated sensors and IoT connectivity allow for real-time monitoring and predictive maintenance, which can significantly decrease downtime and operational costs. With these enhancements, buyers globally can expect a more reliable and efficient hydraulic system capable of meeting the challenges of modern industrial demands.

In the evolving landscape of hydraulic valve production, understanding the quality standards is crucial for global buyers looking to make informed decisions in 2025. With the rising complexity in manufacturing processes and stringent regulatory requirements, companies must adopt robust quality control measures. The recent discussions on the decellularization of heart valves highlight the necessity of standardized processes to ensure that critical parameters are consistently met, reflecting the need for high-quality outputs across various industries.

For buyers, prioritizing suppliers that employ advanced technologies like additive manufacturing can significantly influence the overall quality and efficiency of hydraulic valve production. Companies that leverage automation in their testing and production processes, such as through the use of robotics, can achieve higher precision and reliability in their outputs.

Tips: When evaluating potential suppliers, ensure that they adhere to recognized quality certifications and standards. Additionally, consider their approach to innovation, as investment in new technologies often correlates with superior product quality. Finally, engage with suppliers that demonstrate a commitment to sustainability and efficiency, as these factors are increasingly important in today's market.

The hydraulic valve market is witnessing transformative trends that globally influence buyer decisions. Growing demands for energy efficiency and automation in various industries are propelling the adoption of advanced hydraulic technologies. As manufacturers prioritize sustainability, innovations like variable displacement pumps and electro-hydraulic actuators are becoming increasingly popular, allowing for more precise control and reduced energy consumption in hydraulic systems.

The hydraulic valve market is witnessing transformative trends that globally influence buyer decisions. Growing demands for energy efficiency and automation in various industries are propelling the adoption of advanced hydraulic technologies. As manufacturers prioritize sustainability, innovations like variable displacement pumps and electro-hydraulic actuators are becoming increasingly popular, allowing for more precise control and reduced energy consumption in hydraulic systems.

Tips for buyers include evaluating the compatibility of new technologies with existing systems to ensure a seamless integration. Buyers should also consider the long-term maintenance costs and availability of support services when selecting hydraulic valves. By examining the durability and performance metrics of different valve options, buyers can make informed decisions that align with their operational goals.

Furthermore, staying updated on regulatory changes and industry standards is crucial. Buyers should engage with suppliers who provide insights into emerging regulations affecting hydraulic systems. This proactive approach not only enhances compliance but also ensures that investments made today will remain viable in the evolving landscape of hydraulic technology.