In the rapidly evolving landscape of hydraulic machinery, piston pumps have emerged as vital components in various industrial applications, owing to their unparalleled efficiency and reliability. According to recent market insights from reputable industry reports, the global piston pump market is projected to reach approximately $16 billion by 2026, driven by advancements in technology and increasing demand across sectors such as oil and gas, automotive, and manufacturing.

China's leading manufacturers have significantly contributed to this surge, leveraging innovation and precision engineering to produce high-quality piston pumps that meet international standards. These companies not only dominate the domestic market but are also making notable inroads into global markets, showcasing their products' unmatched performance and durability. This blog delves into how these high-caliber Chinese piston pumps are transforming industry benchmarks and setting the stage for future growth and technological breakthroughs.

Piston pumps are critically acclaimed for their versatility and precision across various industries, including oil and gas, pharmaceuticals, and water management. According to a report by MarketsandMarkets, the global piston pump market is projected to reach $9.3 billion by 2025, growing at a CAGR of 6.1%. This remarkable growth is driven by the increasing demand for efficient fluid transfer solutions that ensure operational excellence and reliability.

In the oil and gas industry, piston pumps are used extensively for crude oil extraction and enhanced oil recovery techniques, contributing to enhanced production levels.

In the oil and gas industry, piston pumps are used extensively for crude oil extraction and enhanced oil recovery techniques, contributing to enhanced production levels.

In the pharmaceutical sector, the need for hygienic and precise pumping systems cannot be overstated. Piston pumps are favored for their ability to handle viscous and shear-sensitive fluids, making them ideal for processes such as drug formulation and vaccine production. The global pharmaceutical manufacturing industry is anticipated to exceed $1.5 trillion by 2025, fueling the demand for advanced pumping technologies.

Furthermore, in water management systems, these pumps facilitate effective wastewater treatment and distribution of clean water, showcasing their essential role in sustainable development initiatives worldwide.

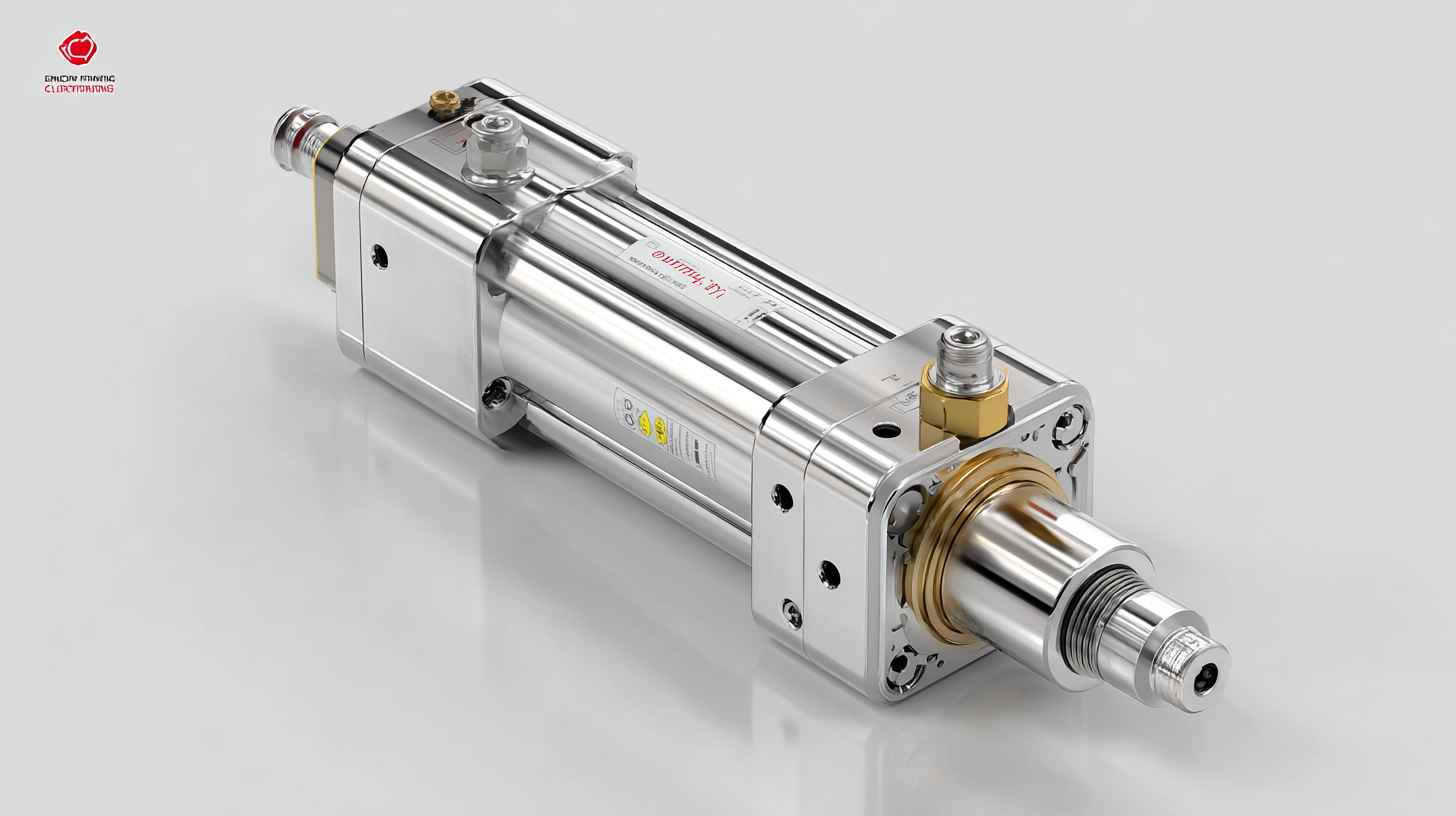

China's leading piston pumps have redefined the benchmarks of quality and innovation in the global market. These state-of-the-art machines combine cutting-edge technology with precision engineering to deliver unmatched performance. Key features of these pumps include advanced sealing systems that enhance reliability and longevity, as well as smart sensors that provide real-time monitoring of performance metrics. Such innovations not only improve efficiency but also reduce maintenance costs, making Chinese piston pumps highly competitive on a global scale.

Tips for selecting the right piston pump often center around understanding your specific needs and the application environment. For instance, consider the pump’s flow rate and pressure characteristics to ensure compatibility with your system. Additionally, look for models equipped with easy access to replacement parts and technical support, as this can significantly reduce downtime and enhance operational efficiency. Investing in a pump that meets international quality standards will ensure durability and consistent performance, making it a prudent choice for both short and long-term projects.

Furthermore, be aware of the integration of modern technology in these pumps. Features such as variable speed drives and adaptive control systems allow for greater flexibility in operation, adapting to diverse working conditions and maximizing energy use. This adaptability is crucial for industries ranging from manufacturing to agriculture, ensuring that China's piston pumps continue to set global standards and delight customers worldwide.

| Feature | Description | Market Impact | Technological Innovation |

|---|---|---|---|

| High Efficiency | Optimized design for maximum energy conversion. | Increased appeal in energy-conscious markets. | Use of advanced materials to reduce friction. |

| Precision Engineering | Tight tolerances ensure consistent performance. | Enhanced product reliability boosts customer trust. | Integration of CNC machining techniques. |

| Durability | Engineered for longevity under extreme conditions. | Lower lifecycle costs for end-users. | Adoption of corrosion-resistant coatings. |

| Versatility | Compatible with a wide range of fluids. | Appeals to diverse industries such as agriculture and manufacturing. | Advanced fluid dynamics simulations in design. |

| Smart Technology | Integration with IoT for real-time monitoring. | Enables predictive maintenance and operational efficiency. | Use of AI algorithms for performance analytics. |

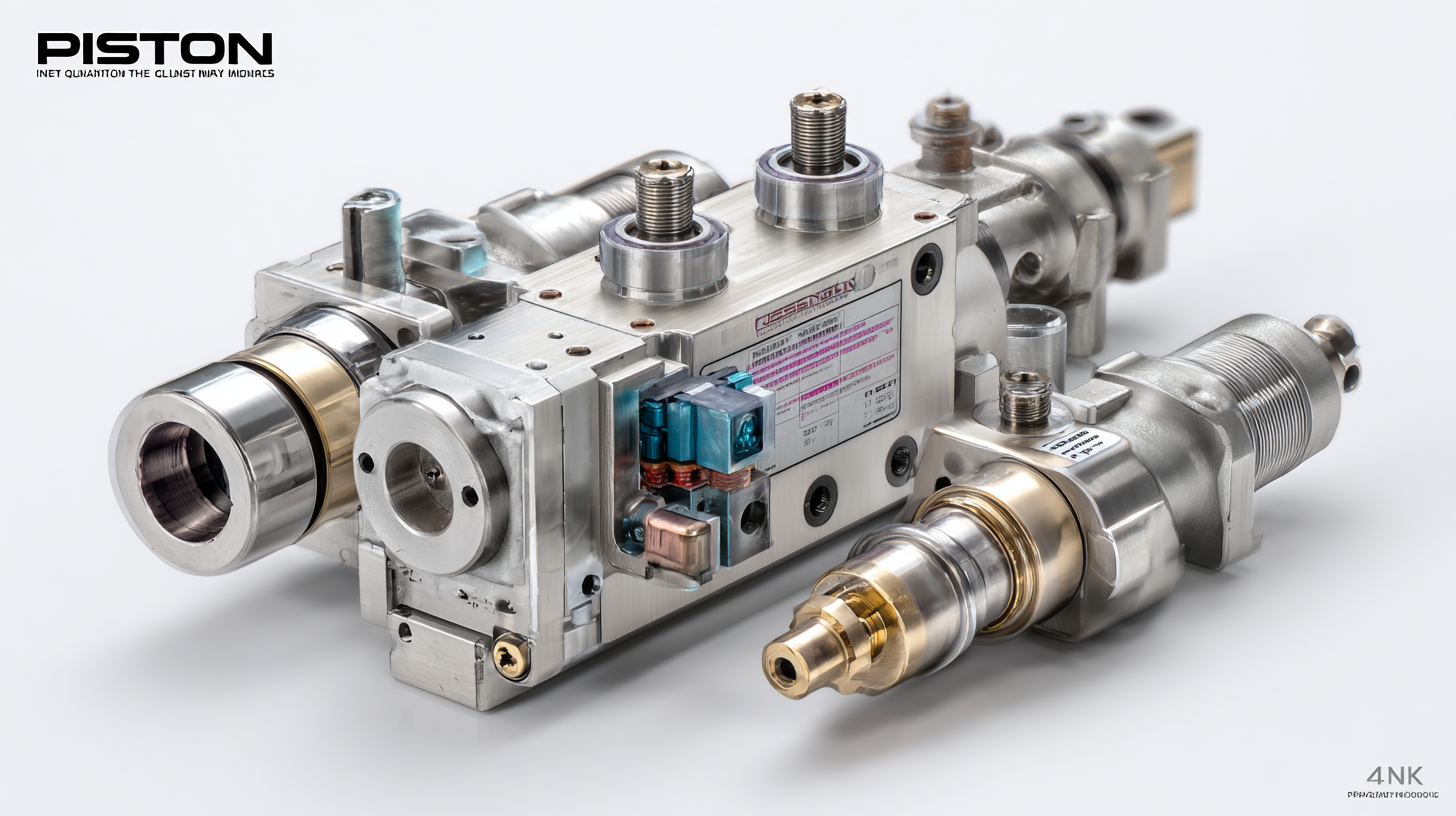

In the realm of piston pumps, understanding the various types available is vital for maximizing efficiency and innovation. Different variants of piston pumps are designed to cater to specific applications and performance needs. For instance, gear pumps, diaphragm pumps, and hydraulic piston pumps each offer unique benefits, such as enhanced precision in pressure control and adaptability to different fluids. These distinctions allow manufacturers to meet diverse market demands more effectively.

Tips for selecting the right piston pump variant include assessing your specific application requirements, such as flow rate and pressure needs. Consider how each pump's design impacts its maintenance and operational costs, as well as its suitability for the substances being handled. Additionally, leverage manufacturer insights and case studies on successful implementations to inform your choices.

As seen in various industries, offering multiple variants can significantly benefit manufacturers. This strategy not only improves customer satisfaction by providing tailored solutions but also aids in resource optimization and reduces operational redundancies. By embracing such a multifaceted approach, companies can stay ahead in the competitive landscape, ensuring that they deliver unmatched quality to their global clientele.

China’s piston pumps have made significant strides in international markets, showcasing their unmatched quality through innovative designs and precise engineering. A notable case study involves a Chinese manufacturer that partnered with a leading European construction firm to provide hydraulic systems for large-scale projects. By customizing their piston pumps to meet specific operational requirements, they not only enhanced performance but also reduced maintenance costs, proving their capability in demanding environments.

Another success story comes from the agricultural sector, where a Chinese company introduced advanced piston pumps to Australian farms. By integrating smart technology, these pumps optimized water usage and increased crop yields. The seamless adaptation to local farming conditions exemplifies how understanding market needs can lead to successful outcomes abroad.

**Tip:** When entering international markets, focus on local partnerships. Collaborating with established firms can provide valuable insights into specific industry demands and regulatory requirements.

**Tip:** Investing in R&D is crucial. Tailoring products to meet regional standards and preferences can significantly enhance competitiveness and market penetration.

The future of piston pump technology is being shaped significantly by innovations emerging from China, a crucial player in the global manufacturing landscape. According to a report by the International Federation of Robotics, China accounted for over 40% of the world's industrial robots installed in recent years, illustrating the country's commitment to automation and efficiency in production lines that include piston pumps. This shift towards advanced manufacturing technologies enhances precision and consistency in product quality, allowing Chinese manufacturers to meet the growing demands of international markets.

In addition to automation, there is a strong focus on developing eco-friendly piston pump technologies. The market for green pumps is projected to reach $30 billion by 2025, mainly driven by energy efficiency regulations and increasing environmental awareness among consumers. Companies in China are pioneering innovations in this area, utilizing materials and designs that not only reduce energy consumption but also minimize waste during manufacturing. This trend positions Chinese piston pump manufacturers at the forefront of sustainable practices, catering to a global market that increasingly prioritizes environmental impact.

This bar chart illustrates key performance metrics of piston pumps from China, showcasing their dominance in the global market through innovation and precision. The data includes market share percentage, innovation index, precision rating, and export volume in units.