In the competitive landscape of fluid transfer technology, the

Piston Pump remains a critical player, offering

unparalleled efficiency and versatility across various industries. As we approach the market

analysis of 2025, it becomes essential to explore what distinguishes

the top-performing Piston Pumps from their competitors. This blog will delve into the key features

and innovations that set these pumps apart, including advancements in materials, design optimizations,

and enhanced performance metrics. By examining trends and forecasts for the future of Piston Pumps,

we aim to provide insights that will not only guide purchasing decisions but also highlight the

emerging technologies shaping this vital segment of the market.

Join us as we uncover the characteristics that make the best Piston Pumps stand out in an ever-evolving industry.

Join us as we uncover the characteristics that make the best Piston Pumps stand out in an ever-evolving industry.

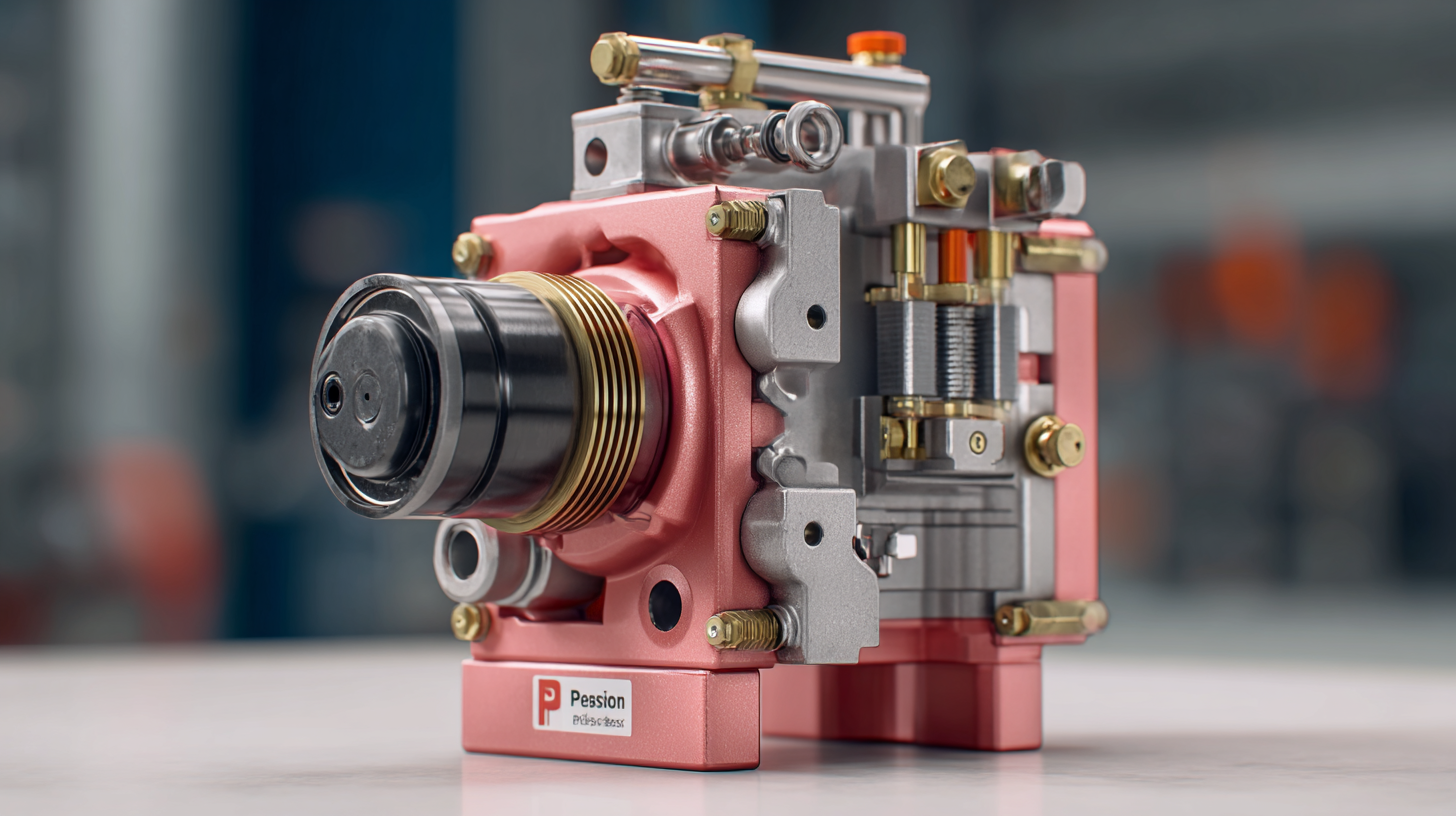

When searching for a high-performance piston pump, several key features should set the best models apart from their competitors. First and foremost, look for superior build quality, which typically involves materials resistant to wear and corrosion. Pumps made with high-grade stainless steel or specialized alloys can maintain efficiency and durability under heavy workloads. Additionally, an effective sealing system is crucial to prevent leaks and ensure optimal operation, protecting the internal components and enhancing the lifespan of the pump.

Another critical feature to consider is the pump's flow rate and pressure capabilities. A top-tier piston pump should have adjustable settings that allow for fine-tuning according to specific applications. This flexibility is essential for various industries, from automotive to manufacturing, where different tasks require varying levels of pressure and flow. Furthermore, advanced technological integration, such as smart monitoring systems, can provide real-time data for maintenance and performance assessment, making it easier to maximize operational efficiency and minimize downtime.

When comparing piston pumps, performance metrics play a crucial role in determining which model stands out in a crowded marketplace. Key performance indicators such as flow rate, efficiency, and pressure output are essential for assessing a pump's capability. Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), dictates how effectively a pump can move fluids. A higher flow rate can significantly enhance productivity in industrial applications, making it a critical factor when evaluating potential purchases.

Efficiency is another vital metric that sets the best piston pumps apart from their competitors. This refers to the pump’s ability to convert energy into fluid movement without significant losses. An efficient pump not only saves on operational costs but also reduces the environmental footprint of a facility. In addition to efficiency, pressure output must be considered, as it affects the pump's ability to handle various applications, from simple fluid transfer to demanding high-pressure operations. By closely examining these performance metrics, buyers can make informed decisions and select the piston pump that best meets their operational needs.

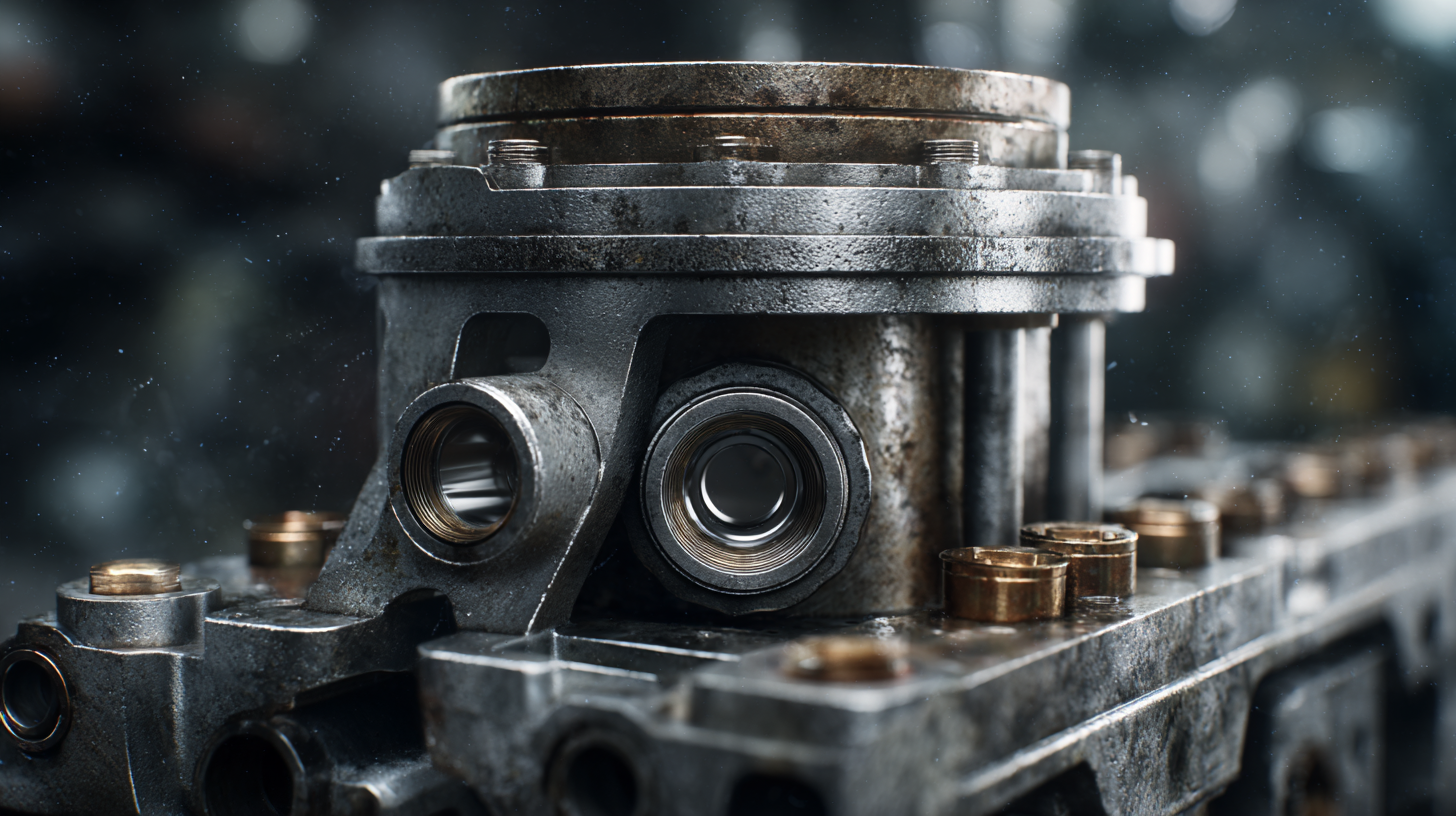

When it comes to piston pumps, the quality of materials used in their construction is paramount for ensuring durability and overall performance. A recent industry report by the Hydraulic Institute highlights that pumps made from high-grade materials can extend operational lifespan by up to 30%, significantly reducing maintenance costs and downtime. This data illustrates that investing in superior materials not only enhances durability but also provides a competitive edge in reliability, which is crucial in demanding applications such as hydraulic systems and industrial processes.

Furthermore, specific materials such as stainless steel and high-density polyethylene have been shown to resist wear and corrosion, key factors in the longevity of piston pumps. According to a study conducted by the American Society of Mechanical Engineers, piston pumps utilizing these materials demonstrate a decrease in failure rates by more than 25% compared to those using lower-quality alternatives. This emphasis on material quality is essential for manufacturers looking to ensure their pumps remain functional under high pressures and challenging environmental conditions, thereby reinforcing their reputation in a crowded market.

Innovative technologies are reshaping the landscape of piston pumps, positioning the best models ahead of their competitors. Recent reports from the Global Pumps Market Research indicate that advancements in materials and precision engineering significantly increase the efficiency and durability of these pumps. For instance, the use of advanced ceramic materials in the design allows for reduced wear and tear, enhancing lifespan by up to 30%, a critical factor for industries relying on consistent performance.

Moreover, the integration of IoT (Internet of Things) technology is revolutionizing how piston pumps are monitored and maintained. According to a study by Freedonia Group, the market for IoT-enabled pumps is anticipated to grow by 25% annually. Sensors embedded in piston pumps enable real-time monitoring of performance metrics, leading to predictive maintenance and minimizing downtime. This technological evolution facilitates smarter operational strategies, ensuring that organizations can respond proactively to potential issues before they escalate, ultimately giving the best piston pumps a competitive edge in an ever-evolving marketplace.

When selecting a piston pump, one of the key considerations is striking the perfect balance between cost and quality. Many manufacturers offer a range of products that boast impressive features, but understanding how to differentiate between genuine quality and marketing gimmicks can save both time and money. It's crucial to look beyond the initial price and evaluate the long-term performance and reliability of the pump. A lower-priced option may seem enticing, but if it fails to perform efficiently, the cost of repairs and downtime will quickly overshadow the savings.

Just as in the world of automotive performance, where balancing various components is vital for achieving optimal functionality, the selection of a piston pump requires a careful evaluation of its specifications and performance metrics. Potential buyers should weigh factors such as material durability, ease of maintenance, and the pump's operational efficiency to find the right match for their needs. This balancing act is essential for ensuring that the pump not only fits within budget constraints but also meets the demanding standards of performance in various applications. By focusing on this equilibrium, users can confidently invest in a piston pump that meets their operational requirements while providing lasting value.